State-of-the-art metal manufacturing technology arrives in Melbourne

On Tuesday 29 October, Assistant Minister for Education Anthony Chisholm visited CSIRO’s Lab22 Innovation Precinct in Clayton Victoria to see the specialist equipment and expertise now available through the Resources Technology and Critical Minerals Trailblazer for industry partners and researchers.

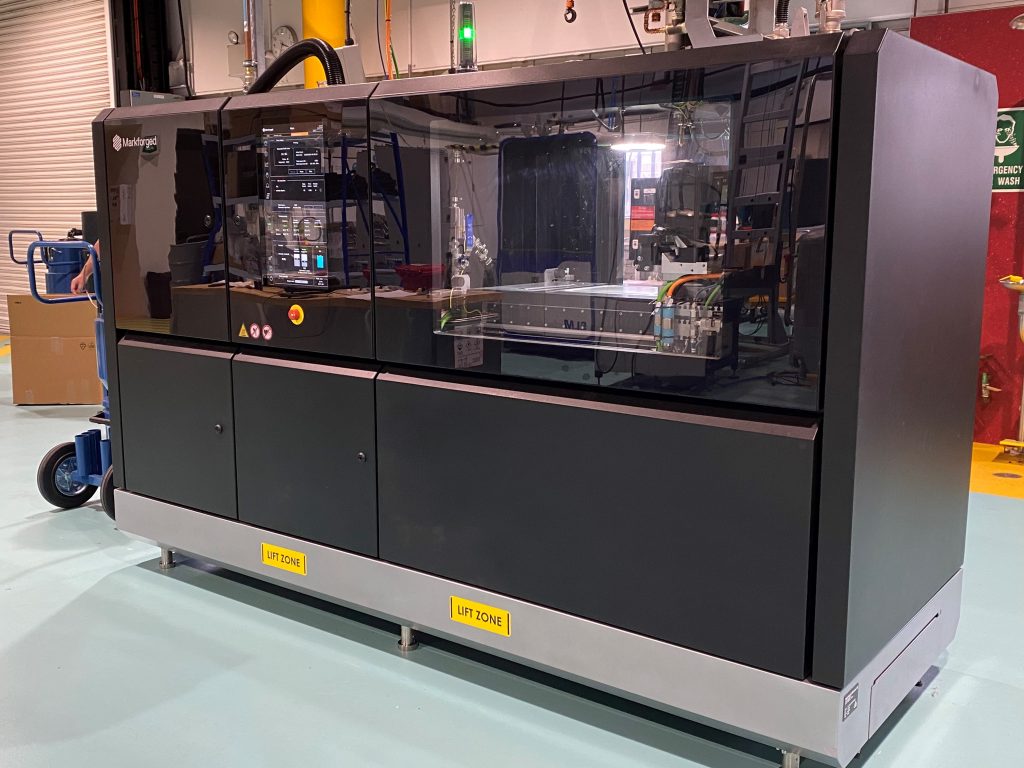

The Markforged’s PX100 Binder Jetting System – now available – and Tekna’s Teskpero-15 Spheriodiser – due to arrive in February 2025 – are two pieces of advanced technology acquired through a $45 million partnership with the Australian Government and Australia’s national science agency to advance Australia’s precision manufacturing capabilities as part of the Trailblazer Universities Program.

The equipment offers researchers and industry unique advantages in the resources and critical minerals sector through the way they offer improved production efficiency, enhanced quality and precision, and cost competitiveness compared to traditional metal manufacturing processes.

The Trailblazer’s presence and access at Lab22, and other CSIRO facilities nationwide, allows us to collaborate with industry partners on projects that require cutting edge equipment to drive new innovations without the need for large investments in expensive technology.

Assistant Minister Chisholm said the investment by the government into this new technology would unlock multiple benefits for Australia’s broader industrial sectors with the iLAuNCH Trailblazer, Defence Trailblazer, and Food and Beverage Accelerator (FABA) also setting up teams in the Lab22 facility.

“The cutting-edge equipment at this lab enables researchers and businesses to build complex metal parts quickly and at scale and save production costs,” Assistant Minister Chisholm said.

“This technology builds on Australia’s natural advantages in having top-ranking reserves of metal ores.”

TECHNICAL SPECIFICATIONS OF RTCM CSIRO EQUIPMENT:

- PX100 Binder Jetting System

- Markforged’s PX100 combines production speed additive fabrication with industry leading part resolution, providing a cost competitive alternative to conventional metal manufacturing. This unlocks high-volume metal production, enabling companies to exercise more control over their production process.

- Teskpero-15 Spheriodiser

- Tekna’s Teskpero-15 is designed for the development and production of new spherical powders. The system improves powder flowability, reduces internal porosity, and provides higher packing density, outcomes necessary for meeting the most demanding powder metallurgy applications such as additive manufacturing (i.e. 3D printing of metals like stainless steel, titanium, nickel alloys) metal injection molding (i.e. Producing small, complex parts with good performance), Thermal spray (i.e. Wear and corrosion resistant coatings), etc.

Researchers and industry partners working towards developing exciting solutions for the resources and critical minerals sector that could benefit from the use of this technology are encouraged to reach out to our team at trailblazer@curtin.edu.au for more information.

Latest News & Events

Showcase Explores Path To Viable Critical Minerals Sector in Townsville